Projects

Development of Innovative Manufacturing Processes for Quantum Dot Arrays and Nano-energy Devices

Name

Kazuhiko Endo

Professor

Green Nanotechnology Laboratory , Institute of Fluid Science

Outline of Research

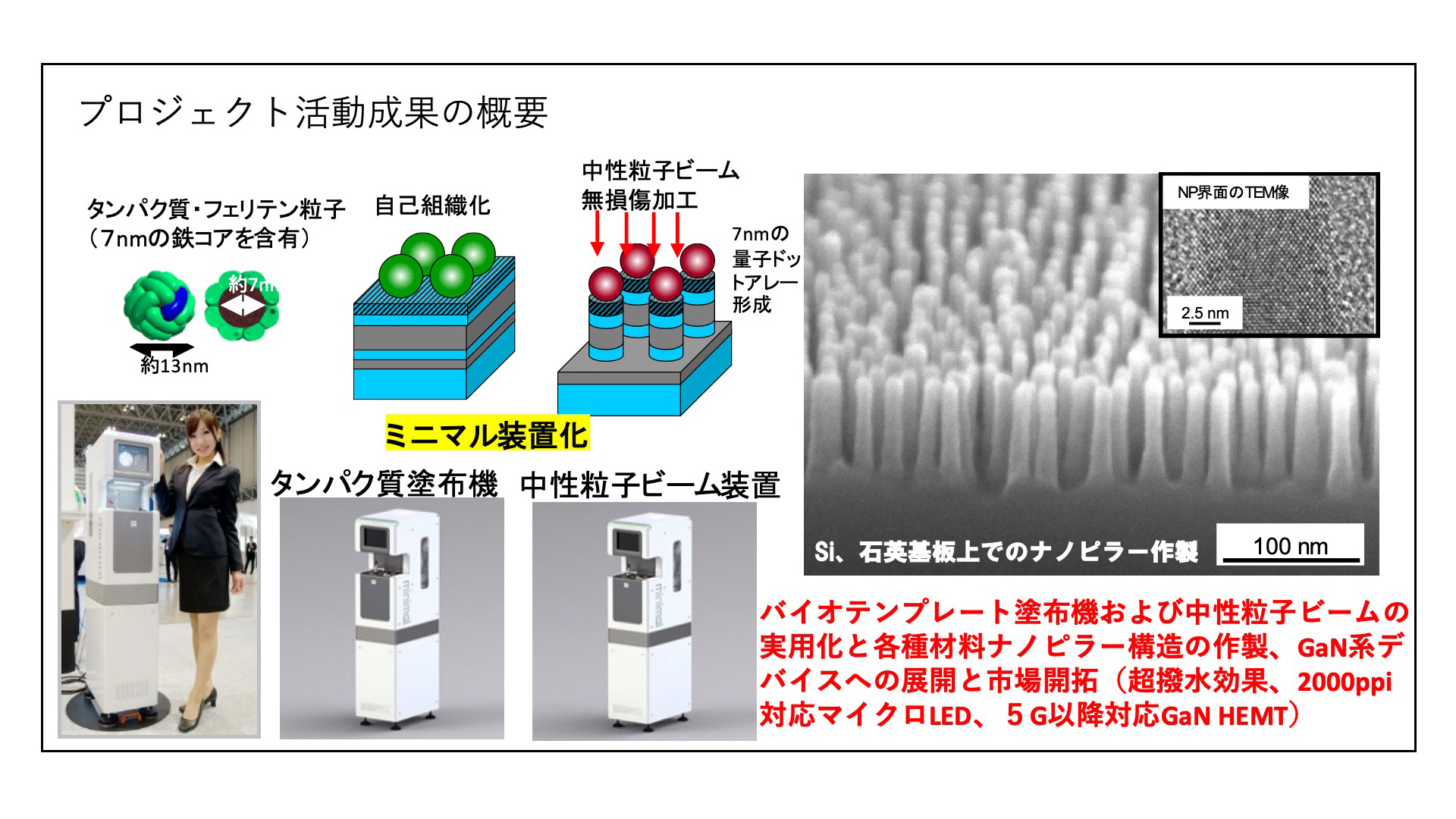

This project is part of the industry–government–academia collaborative research of the Consortium for Advanced Energy Devices Technology, which was established with the support of the Ministry of Economy, Trade and Industry’s (METI’s) Industry–Academia Collaboration Innovation Promotion Project. This project aims to utilize our “bio-template ultimate etching technology” to develop and demonstrate the practicality of high-efficiency quantum dot solar cells with an energy conversion efficiency of 30% or higher, quantum dot thermoelectric conversion devices that generate 100 µW/cm2 or higher, and phonon transport-controlled high-mobility semiconductor devices.

In particular, the project focuses on the establishment of the manufacturing process using a practical, high-precision protein coating machine and neutral beam process system, which were developed under the METI’s Strategic Basic Technology Upgrading Support Project (Future of Supporting Industry). In collaboration with the National Institute of Advanced Industrial Science and Technology (AIST), we are studying the development of a stable manufacturing process and equipment for quantum dot array structures. Together with AIST, we are also developing quantum dot lasers/LEDs and micro-LEDs, which are energy-saving devices that utilize quantum dots. This industry–government–academia collaborative research aims to develop the world’s first practical quantum dot fabrication process and equipment and to develop practical nanodevices.

Research Purpose

Tohoku University; AIST; Nagase & Co., Ltd.; Litho Tech Japan Co., Ltd.; and SPP Technologies Co., Ltd. have established a vertically integrated consortium called the Bio-Template Ultimate Top-down Processing Core Technology Consortium. Bio-template ultimate etching processing can fabricate nanopillar structures of various materials such as silicon and quartz, which are used in the development of nano-energy devices and high-mobility semiconductors. In addition, fabricating nanopillar structures on the surface of quartz and organic materials can facilitate the control of surface wettability and sterilization effects. This technology will be developed for components for automobiles, information equipment and medical devices.

Expected Effect

It is difficult to achieve superhydrophobicity by controlling only the surface free energy of coatings and other materials, and there are problems with durability and reliability. Therefore, a surface microstructure is necessary to control hydrophobicity. By applying the nanostructures fabricated by this method to the surface of any material, it can be utilized in communication devices, optical devices, lens systems, and other devices whose performance is degraded by moisture and dirt adhesion. The implementation of technology, which could replace surface coatings and offer a high degree of control, durability, and reliability, would have an immense impact on society. Furthermore, fabricating μ-LEDs using this method would facilitate the creation of directional high luminous efficacy LEDs with a pillar structure smaller than 6 μm in diameter—a feat that would be the first of its kind in the world.

Achievement

Through the Strategic Basic Technology Upgrading Support Project (Future of Supporting Industry), an industry–academia–government collaborative project promoted by METI from FY2016 to FY2018, we have successfully developed a bio-template ultimate top-down processing system consisting of a protein coating machine and a neutral beam etching system. With this achievement, we realized our initial goal of forming nanopillar structures on various small-caliber substrates in large quantities in a stable manner.

Joint Research Enterprise

Beginning with the Strategic Basic Technology Upgrading Support Project (Future of Supporting Industry), which started in FY2016 and ended in FY2018, Tohoku University; AIST, Nagase & Co., Ltd.; Litho Tech Japan Co., Ltd.; and SPP Technologies Co., Ltd. launched the Bio-Template Ultimate Top-down Processing Core Technology Consortium in FY2019 to realize a vertically integrated collaboration. In the future, other device and system manufacturers will also take part in the consortium to develop practical technological applications through international industry–academia collaborations.

Keywords

Bio-template ultimate top-down processing, nanostructure, surface wettability control, micro-LEDs, nanoenergy devices

Contact Information

TEL:+81-22-217-5240

E-mail address: kazuhiko.endo.d6*tohoku.ac.jp

Please use @ instead of *.

HP URL: http://www.ifs.tohoku.ac.jp/samukawa/